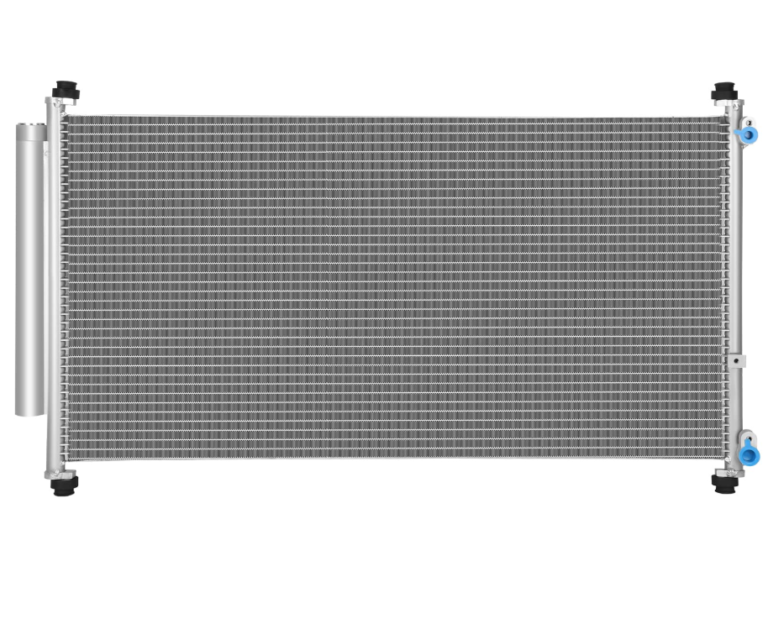

The term mechanical radiators is not commonly used in modern automotive or industrial cooling systems. However, it typically refers to radiator systems that rely on mechanical power or components for operation. These systems are often found in older vehicles or specific applications where mechanical components like fans or pumps are used to enhance cooling performance. In modern vehicles, radiators function by circulating coolant and using airflow to dissipate heat, often without the complexity of mechanically driven components.

Functions and Role of Mechanical Radiators

- 1. Heat Dissipation:

- • The primary function of any radiator, including mechanical ones, is to dissipate heat generated by the engine, equipment, or mechanical system into the surrounding air. Heat is transferred through the radiator’s metal surfaces, commonly made from materials like copper or aluminum, which offer excellent thermal conductivity.

- 2. Coolant Circulation:

- • Mechanical radiators often include pumps (such as water pumps) that help circulate coolant between the engine and the radiator. This ensures continuous absorption and removal of heat from the engine. These pumps may be driven by the engine itself or by separate mechanical means.

- 3. Enhanced Cooling Through Mechanical Power:

- • Many mechanical radiator systems utilize mechanical devices like fans or blowers to improve airflow. Historically, mechanical fans driven by engine belts were common, spinning in sync with the engine’s RPM. This increased airflow over the radiator, boosting heat dissipation.

- 4. Preventing Overheating:

- • Mechanical radiators play a vital role in maintaining optimal operating temperatures for engines and equipment. Insufficient cooling can lead to overheating, causing increased wear, reduced efficiency, and potentially catastrophic damage.

- 5. Adaptability to Harsh Environments:

- • Mechanical radiators are often found in older vehicles, heavy machinery, and motorcycles, where cooling systems rely on mechanical fans or other mechanical components to function effectively, even under heavy workloads or in extreme conditions.

Common Components of Mechanical Radiators

- • Radiator Core:

The central structure, often made of aluminum or copper, facilitates heat transfer from the coolant to the surrounding air. - • Mechanical Fan:

Driven by mechanical power, usually from the engine’s belt, the fan increases airflow across the radiator, improving heat dissipation. - • Water Pump:

Ensures the continuous circulation of coolant between the engine and radiator. - • Coolant Pipes:

Channels that transport coolant between the engine, radiator, and other system components.

Advantages of Mechanical Radiators

- 1. Independent of Electrical Power:

- • Mechanical radiators rely on engine power rather than external electrical systems, making them advantageous in environments where electrical power is unavailable or unreliable.

- 2. Simplicity and Reliability:

- • These systems are mechanically straightforward, with fewer electronic components, reducing the likelihood of failure and ensuring reliability.

- 3. Adaptable to Extreme Conditions:

- • In rugged or remote applications, mechanical radiators excel due to their independence from sophisticated electronic controls.

Disadvantages of Mechanical Radiators

- 1. Noise Levels:

- • Mechanically driven fans can be noisy, especially at higher engine speeds, creating a less pleasant operating environment.

- 2. Limited Efficiency:

- • Compared to modern electronic cooling systems, mechanical systems lack precision and efficiency, as they cannot adjust performance dynamically based on system needs.

- 3. Lack of Fine Control:

- • Unlike modern systems with sensors and electronic controls, mechanical systems do not provide automatic adjustments to fan speed or coolant flow, limiting their adaptability to changing conditions.

Modern Alternatives

While mechanical radiator systems remain in use for older vehicles and heavy-duty applications, modern cooling systems increasingly use electric fans, electric water pumps, and electronically controlled systems. These advancements offer:

- • Improved Cooling Efficiency: Dynamic adjustments based on real-time temperature feedback.

- • Energy Savings: Reduced engine load by decoupling cooling components from mechanical drive systems.

- • Enhanced Durability: Electronic systems reduce wear on mechanical parts and offer longer service life.

Conclusion

A mechanical radiator is typically a cooling system that uses mechanical components such as fans or pumps to enhance the circulation of coolant and improve heat dissipation. These systems play a critical role in preventing overheating and maintaining optimal operating temperatures for engines and mechanical equipment. While simple and reliable, mechanical radiators have largely been replaced by more efficient electronic systems in modern vehicles and machinery. However, they remain relevant in older vehicles, heavy machinery, and extreme-use cases where their robustness and independence from electrical systems are advantageous.